Products

- Home

- Products

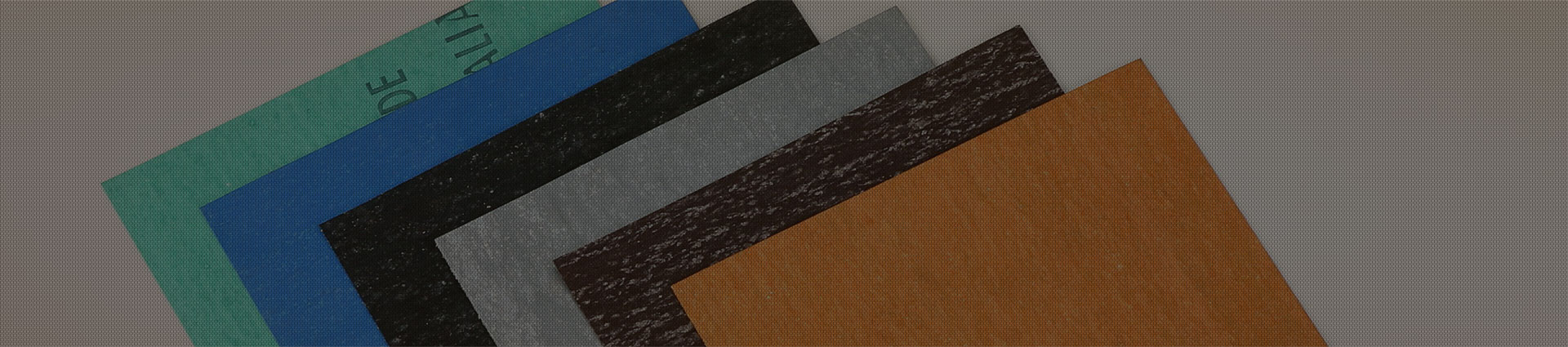

- Asbestos Jointing Sheets

| AC-31 ECO | AC-41 ECO PLUS | AC-51 ECO PLUS | |||||||

| Material Description and Application | Economically priced general purpose jointing for low temperature and low pressure conditions in steam, water and gas lines. | An alternative to TJ-31 ECO with better ageing properties yet economically priced. | A medium grade jointing finding extensive applications across a wide industry segment in steam, water, gas and alkali lines. | ||||||

| Recommended Maximum Operating Temperature and Pressure | Temp | Non-Metallic | Metallic | Temp | Non-Metallic | Metallic | Temp | Non-Metallic | Metallic |

| 350oC | 380oC | 350oC | 380oC | 380oC | 400oC | ||||

| Pressure | 30 kg/cm2 | 35 kg/cm2 | Pressure | 30 kg/cm2 | 35 kg/cm2 | Pressure | 40 kg/cm2 | 45 kg/cm2 | |

| Typical Properties | Tensile Strength (Min.) : 60 kg/cm2 | Tensile Strength (Min.) : 80 kg/cm2 | Tensile Strength (Min.) : 100 kg/cm2 | ||||||

| (For Non-Metallic material) | Density (nominal) : 1.85 gms/cc | Density (nominal) : 1.85 gms/cc | Density (nominal) : 1.9 gms/cc | ||||||

| Compression : 6-14% | Compression : 6-14% | Compression : 6-14% | |||||||

| Recovery (Min.) : 40% | Recovery (Min.) : 40% | Recovery (Min.) : 40% | |||||||

| Loss on Ignition (Max.) : 28% | Loss on Ignition (Max.) : 28% | Loss on Ignition (Max.) : 28% | |||||||

| Specification Compliance | ASTM F104 F112000 M3 | ASTM F104 F112000 M4 IS 2712 / 98 : Grade W/3 |

ASTM F104 F112700 M4 IS 2712 / 98 : Grade W/3 |

||||||

| Standard Size | 1600mm x 1500 mm 1600mm x 3000mm |

1600mm x 1500 mm 1600mm x 3000mm |

1600mm x 1500 mm 1600mm x 3000mm |

||||||

| Standard Thickness | 0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

||||||

| AC-61 EXTRA | AC-71 SUPER | OIL SPECIAL | |||||||

| Material Description and Application | A versatile sealing material specially bonded with superior compounds to handle higher temperature and pressure service conditions in oil, water and gas pipelines and medium temperature oil pipelines | A superior grade of jointing with specially selected chrysotile fibres and heat resisting compounds to handle extreme workings conditions in superheated and saturated steam lines as well as gas, alkali, oil, solvent, chemical, petrochemical and dilute acid lines. | Manufactured with specialty rubbers and high grade fibres to resist the medium flowing through petrochemical, hydrocarbon, solvent and other aromatic compound pipelines | ||||||

| Recommended Maximum Operating Temperature and Pressure | Temp | Non-Metallic | Metallic | Temp | Non-Metallic | Metallic | Temp | Non-Metallic | Metallic |

| 450oC | 480oC | 550oC | 600oC | 550oC | 600oC | ||||

| Pressure | 80 kg/cm2 | 90 kg/cm2 | Pressure | 150 kg/cm2 | 180 kg/cm2 | Pressure | 150 kg/cm2 | 180 kg/cm2 | |

| Typical Properties | Tensile strength (Min.) : 140 kg/cm2 | Tensile strength (Min.) : 250 kg/cm2 | Tensile strength (Min.) : 250 kg/cm2 | ||||||

| (For Non-Metallic material) | Density (nominal) : 1.95 gms/cc | Density (nominal) :1.95 gms/cc | Density (nominal) : 1.95 gms/cc | ||||||

| Compression : 7-12% | Compression : 7-12% | Compression : 7-14% | |||||||

| Recovery (Min.) : 40% | Recovery (Min.) : 40% | Recovery (Min.) : 45% | |||||||

| Loss on ignition (Max.) : 28% | Loss on ignition (Max.) : 28% | Loss on ignition (Max.) : 28% | |||||||

| Stress Relaxation (Min. Residual Stress) : 180kg/cm2 | Stress Relaxation (Min. Residual Stress) : 180kg/cm2 | Stress Relaxation (Min. Residual Stress) : 180kg/cm2 | |||||||

| Specification Compliance | ASTM F104 F112441 M6 IS 2712 / 98 : Grade W/2, O/2 |

ASTM F104 F112231 M7 IS 2712 / 98 : Grade W/1 |

ASTM F104 F112231 M7 IS 2712 / 98 : Grade W/1 IS 2712 / 98 : Grade O/1 |

||||||

| Standard Size | 1600mm x 1500 mm 1600mm x 3000mm |

1600mm x 1500 mm 1600mm x 3000mm |

1600mm x 1500 mm 1600mm x 3000mm |

||||||

| Standard Thickness | 0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

||||||

| Fuel Immersion Properties | Oil No. 3 | Oil No. 3 | Oil No. 3 | ||||||

| Increase in mass (Max.) : 30% | Increase in mass (Max.) : 20% | Increase in mass (Max.) : 15% | |||||||

| Increase in thickness (Max.) : 20% | Increase in thickness (Max.) : 25% | Increase in thickness (Max.) : 25% | |||||||

| Fuel B | Fuel B | Fuel B | |||||||

| Increase in mass (Max.) :25% | Increase in mass (Max.) :20% | Increase in mass (Max.) : 20% | |||||||

| Increase in thickness (Max.) : 20% | Increase in thickness (Max.) : 20% | Increase in thickness (Max.) : 15% | |||||||

| Water | Water | Water | |||||||

| Increase in mass (Max.) :10% | Increase in mass (Max.) :10% | Increase in mass (Max.) : 10% | |||||||

| OIL F | OIL CS | |||

| Material Description and Application | A specially designed variation of TJ Oil ’Special’ having very good Resistance to all oils and fuels as well as steam and water. Ideal for sealing engine parts in the Automobile industry. | This has been specially engineered for applications in following low or fluctuating torque pressures or for sealing of parts having uneven surfaces, specially in the Automobile industry. | ||

| Recommended Maximum Operating Temperature and Pressure | Temp | Non-Metallic | Temp | Non-Metallic |

| 450oC | 500oC | |||

| Pressure | 50 kg/cm2 | Pressure | 100 kg/cm2 | |

| Typical Properties | Tensile strength (Min.) : 280 kg/cm2 | Tensile strength (Min.) : 250 kg/cm2 | ||

| (For Non-Metallic material) | Density (nominal) : 1.95 gms/cc | Density (nominal) :1.95 gms/cc | ||

| Compression : 7-11% | Compression : 7-14% | |||

| Recovery (Min.) : 45% | Recovery (Min.) : 45% | |||

| Loss on ignition (Max.) : 28% | Loss on ignition (Max.) : 28% | |||

| Stress Relaxation (Min. Residual Stress) : 180kg/cm2 | Stress Relaxation (Min. Residual Stress) : 180kg/cm2 | |||

| Specification Compliance | ASTM F104 F112231 M7 IS 2712 / 98 : Grade O/1 |

ASTM F104 F112341 M7 | ||

| Standard Size | 1600mm x 1500 mm 1600mm x 3000mm |

1600mm x 1500 mm 1600mm x 3000mm |

||

| Standard Thickness | 0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

0.4mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 3.0mm Other sizes and thicknesses available on request |

||

| Fuel Immersion Properties | Oil No. 3 | Oil No. 3 | ||

| Increase in mass (Max.) : 20% | Increase in mass (Max.) : 30% | |||

| Increase in thickness (Max.) : 10% | Increase in thickness (Max.) : 25% | |||

| Fuel B | Fuel B | |||

| Increase in mass (Max.) : 20% | Increase in mass (Max.) : 20% | |||

| Increase in thickness (Max.) : 10% | Increase in thickness (Max.) : 25% | |||

| Water | Water | |||

| Increase in mass (Max.) : 10% | Increase in mass (Max.) : 10% | |||